We have installed pressure and temperature sensors, enabling you to check the status and condition of the dust collector in detail.

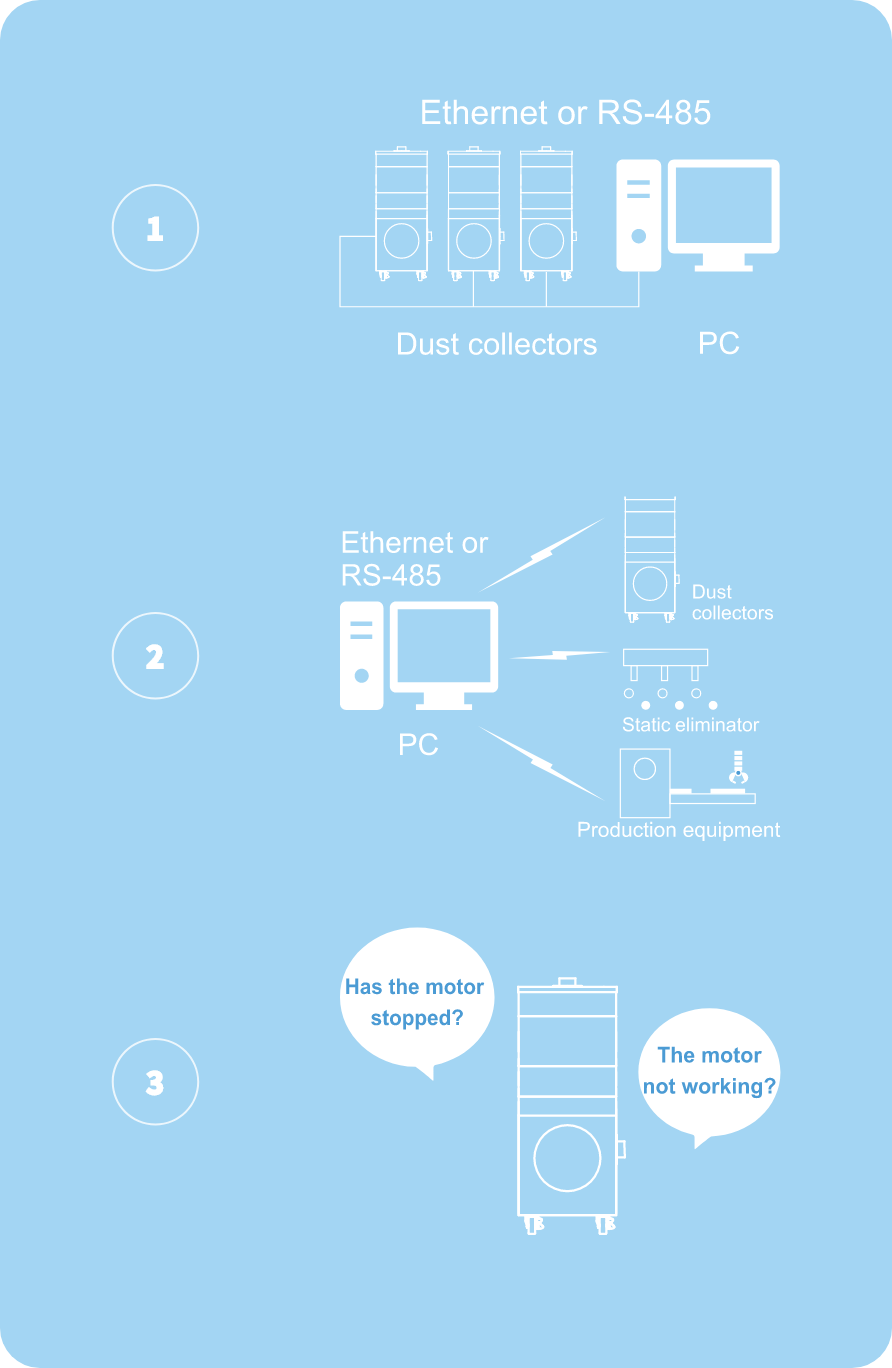

A communication function enables you to control multiple dust collectors as a linked part of your equipment.

By retrieving log data via Ethernet or RS-485 communication,you can check the operational status of the dust collector. *Option required for communication (sold separately)

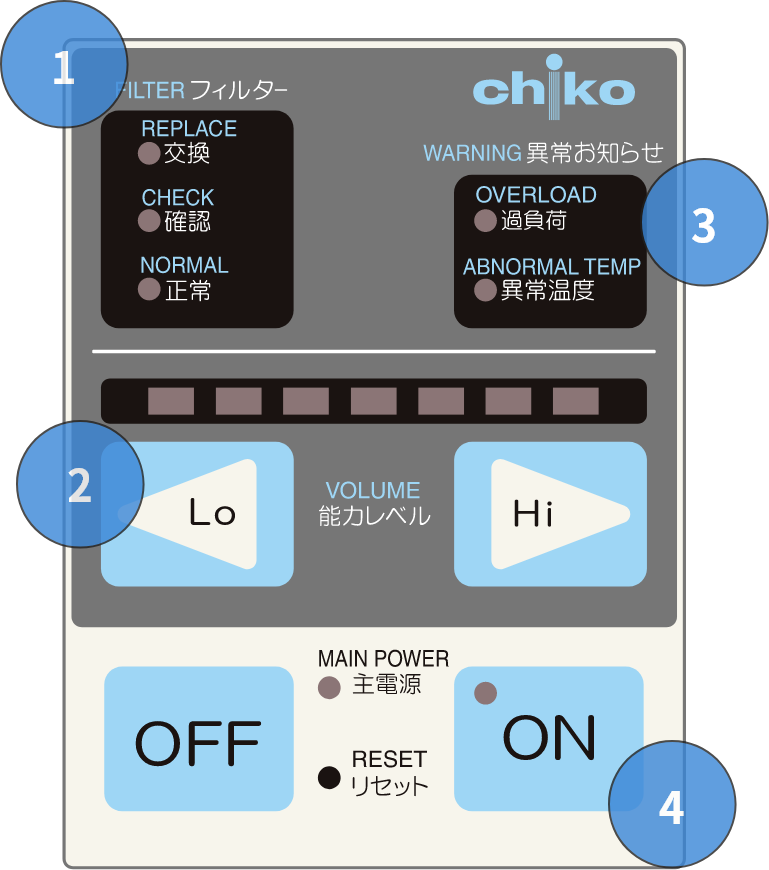

Improved information can be viewed on the updated AT3 panel

You can check 4 pressures. You can monitor the current capability level of the dust collector and the status of each filter.

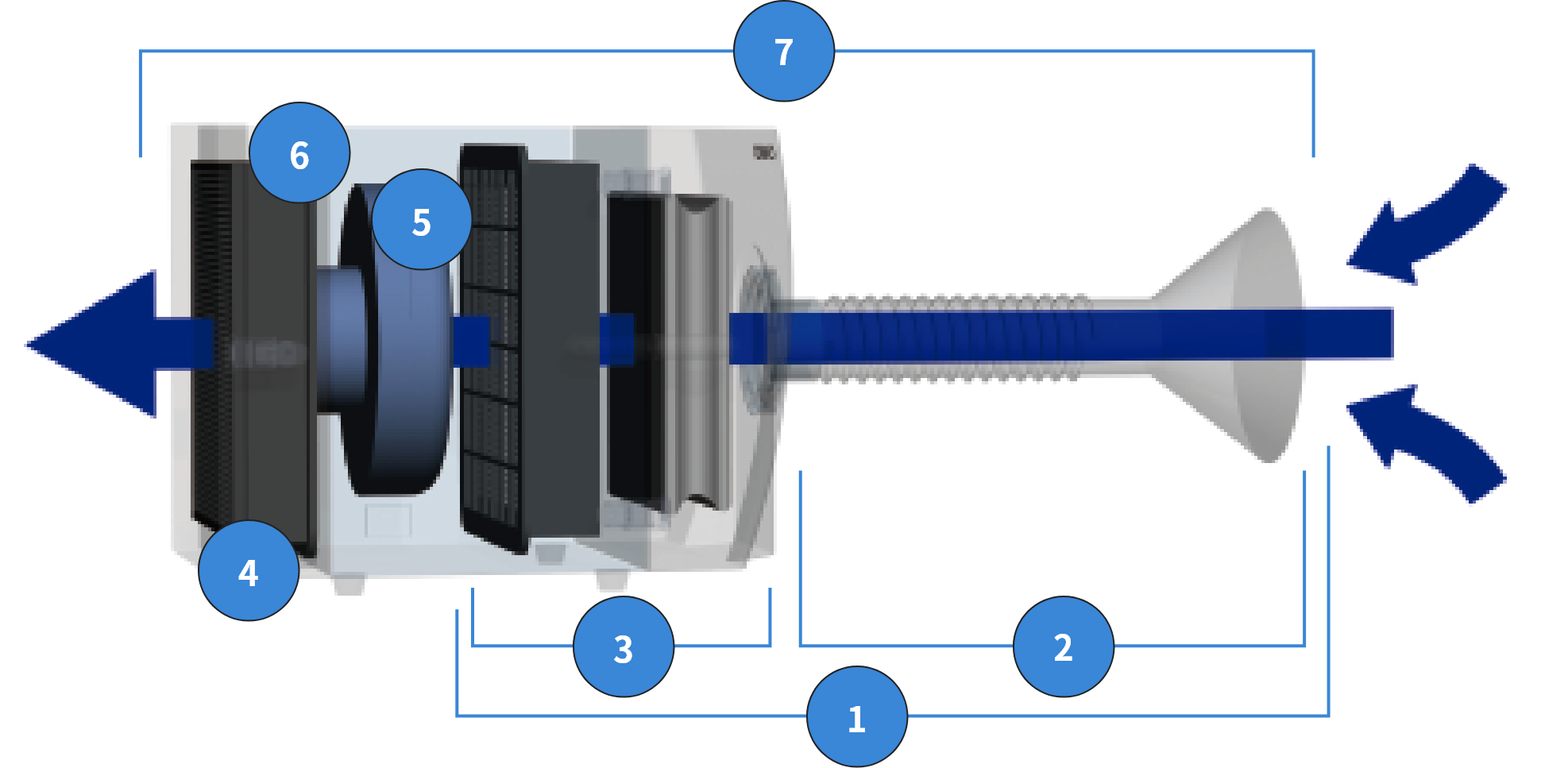

1. Suction pressure

2. Filter differential pressure at the suction side

3. External pressure

4. Exhaust pressure

You can check the temperature of the area around the blower. You can check the rotation speed of the motor, and identify equipment abnormalities early and take rapid countermeasures.

Detects abnormalities in pressure; blower temperature; rotation speed and shows these on the display.

It is also possible to output an error signal via an optional remote cable or optional Ethernet / RS-485 communication.

We have enabled Ethernet / RS-485 communication for the first time in a dust collector.This enables centralized control of multiple units, or in automated/unmanned factories.

By using the built-in lithium ion battery included with the unit, you can log dust collection data. You can save and review past operating conditions on the time axis (every 1h). (Up to 3 months)

By retrieving the logged review data using Ethernet or RS-485 communication, you can now manage the unit from the time it is initialized.

You can also carry out maintenance at appropriate times by using the saved data. If there are any operational issues, it possible to quickly and accurately investigate the causes.

Centralized management of multiple dust collectors.

Centralized management as an integrated device

Check past data and check the status at the time when the issue occurred

resolve the problem smoothly

You can check the differential pressure, external pressure, suction pressure, exhaust pressure, blower speed, operating time using numerical values.

Filter-clogging-notice function installed. Since you can check the differential pressure in the filter, you can accurately assess the state of clogging in the filter.

Alarm function installed (abnormal temperature warning)

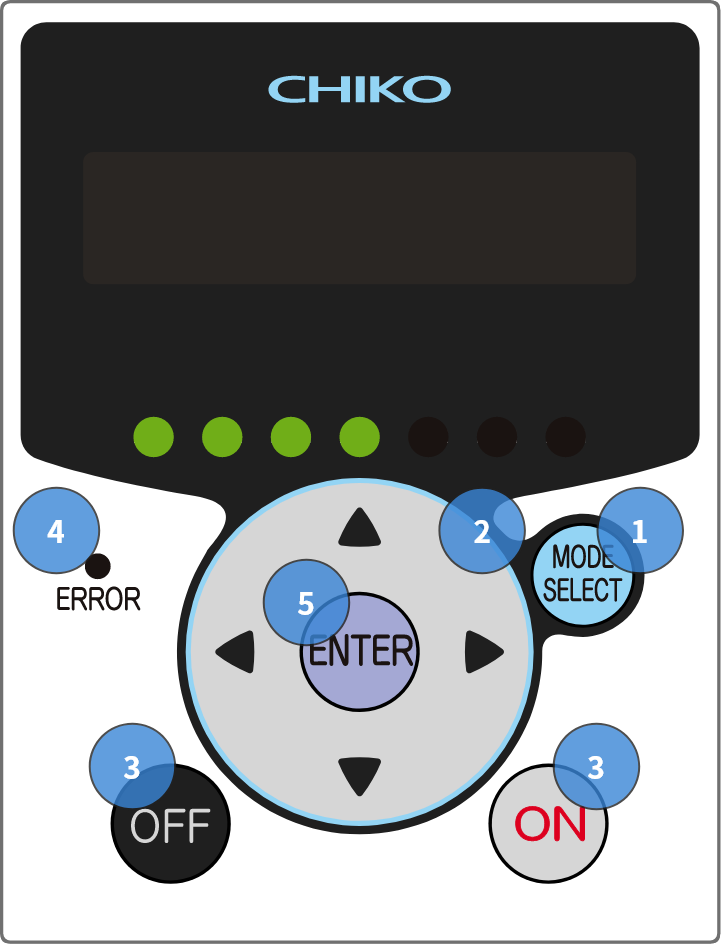

The mode select key operates if pressed when the unit is OFF. This key can also be used to “go back to the previous stage.”

This is used for changing the operating level and selecting / changing items on the display.

Separate to the power ON / OFF function, if you press and hold down the OFF button you register the initial pressure.

This lamp lights up or blinks when an error occurs (insufficient airflow, pressure shortfall, etc.).

Pressing the key, when the mode is selected, will set the contents. Also the initial pressure is registered by pressing and holding down the key during operation.

Note: Please registrate the initial pressure right after you set up the suction hose and hood etc.

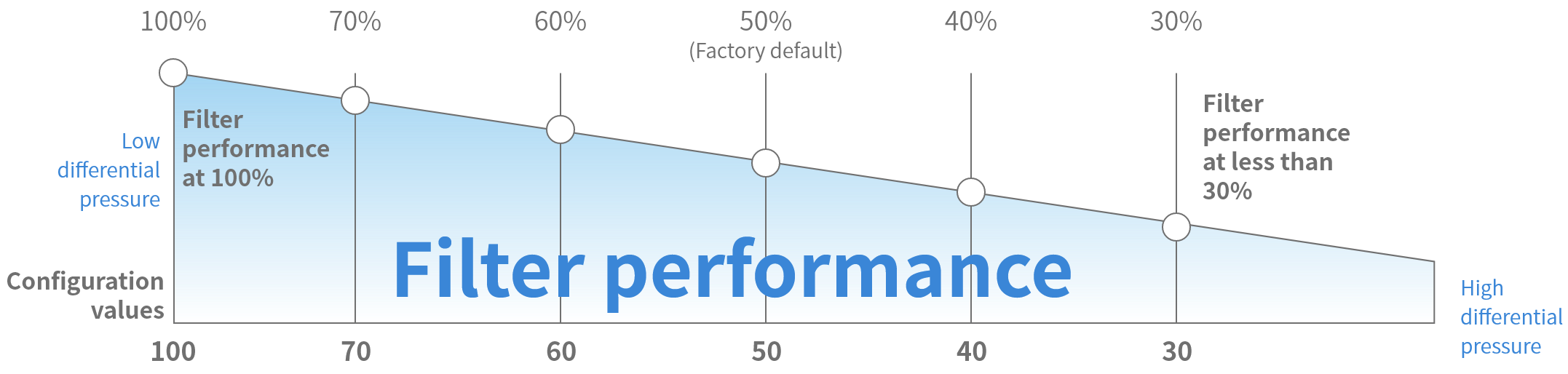

To advance the lamp-lighting timing![]() To laten the lamp-lighting timing

To laten the lamp-lighting timing

WARNING: The timing of the warning light can be set at 5 different levels.

When the level is adjusted after the initial pressure is set, the timing of the WARNING light is set automatically and comes on according to the appropriate pressure. Please note that the warnng light may come on when the operating level is shifted down from 7 to 1 suddenly.

*if the initial pressure is not set, warning light that indicate [initial pressure not registered] will come on.

You can check the total pressure from the suction port to the motor chamber, and the current load.

You can check the suction port and duct pressure. You can assess which nozzle is appropriate at the start, and you can check clogging in the nozzle when in use.

It is possible to check clogging in the suction side filter. You can output a clogging alarm display or signal.

You can check clogging in the exhaust filter and loss of pressure in the exhaust pipe.

You can ensure the device does not stop or fail, due to filter clogging or a rise in temperature because of motor abnormalities.

You can check the number of revolutions while the motor is in use in order to quickly identify motor malfunctions and take countermeasures.

You can check cumulative operating time (from the start of operation) and the current continuous operating time.

Notifies you about the status of clogging.

Adjusts the dust collector suction level. This can be set according to 7 operating levels.

Overload:This lights up when the motor runs at 150% of its specified electrical current level for over 1 minute.This stops the operation of the unit at the same time.

Abnormal temperature: This lights up when the motor reaches an abnormal temperature.This stops the operation of the unit at the same time.

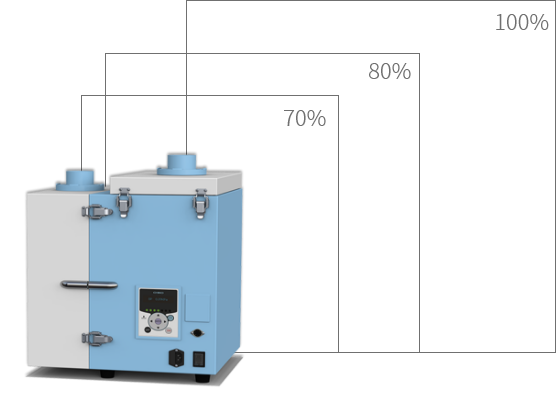

40% smaller than other machines with same performance

1. With high performance exhaust filter(dust collection efficiency: 99% or more of particulates of 0.3μ)

(Optional: HEPA filter), able to be used inside a Clean Room.

2. When it is being operated inside a clean room, there is no need of piping to the outside.

3. No worry that the dust will adhered on the products again.

CHIKO AIRTEC CO., LTD

2-27-24, Hakunoshima, Minoh,

Osaka 562-0012 Japan

E-mail:info@chiko-airtec.jp

CHIKO AIRTEC KOREA CO., LTD

#608 6F. 25-32, 116BUN-GIL, LS-RO, DONGAN-GU,

ANYANG-SI, GYEONGGI-DO SOUTH KOREA

E-mail: bh_lee@chiko-airtec.com