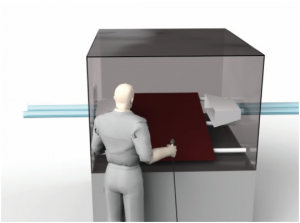

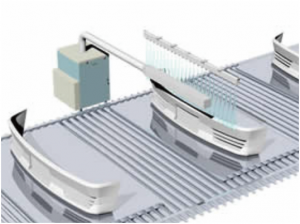

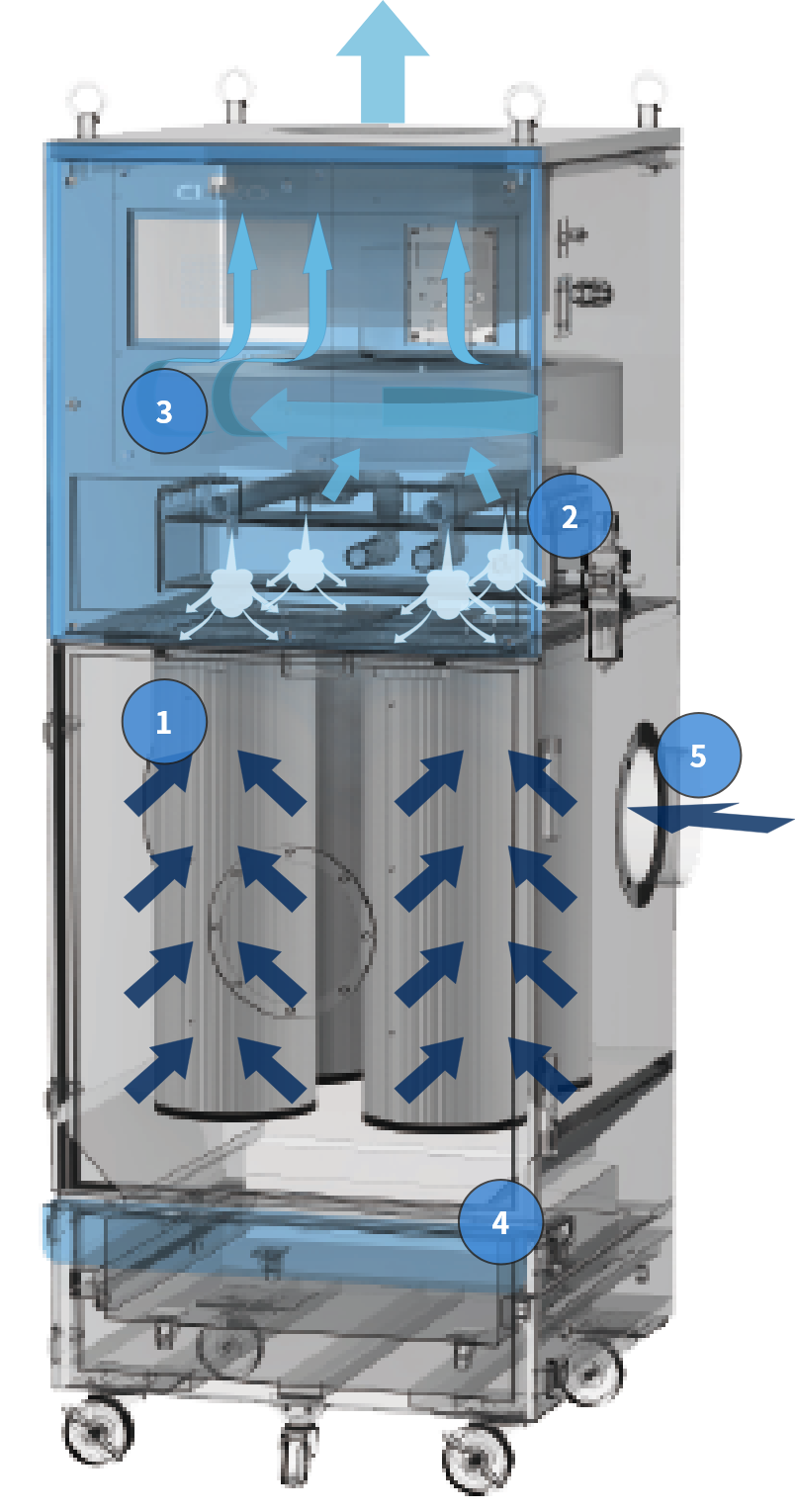

CMP series dust collectors are medium size with medium pressure / high air blower capability.

Suitable for sucking in surrounding air by using a hood with large opening area or by branching to multiple hoses.

| Model | Primary filter | |||

|---|---|---|---|---|

| Common type for standard / custom model | Number | Total filtration area | ||

| CMP-750AT3N | CS-175-300-63P-R | 4 | 6.0㎡ | |

| CMP-1500AT3N | CS-175-500-63P-R | 4 | 10.0㎡ | |

| Model | Air intake and exhaust for cooling inverter | Exhaust HEPA filter

*1

|

|

|---|---|---|---|

| Nonwoven cloth | Filter (when using HEPA filter) | ||

| CMP-750AT3N | PS300N | HEP-1293-33 | HEP-5040-80 |

| CMP-1500AT3N | PS300N | HEP-1293-33 | HEP-5040-80 |

| Model | Output | Voltage | Frequency | Rated current |

|---|---|---|---|---|

| CMP-750AT3N | 1000W | 200V (three phase) | 50/60Hz | 6.5A |

| CMP-1500AT3N | 1500W | 200V (three phase) | 50/60Hz | 9.3A |

| Maximum air flow |

Maximum static pressure |

Noise level

*1

|

Suction port (hose) size |

Compressed air consumption volume |

|---|---|---|---|---|

| 15.0㎥/min | 5.0kPa | 57-68dB | φ125 | 17L/min(Connection port φ8) |

| 27.5㎥/min | 5.0kPa | 57-68dB | φ150 | 17L/min(Connection port φ8) |

| Compressed air pressure |

To be used with 200-240V |

CE compliant | Panel | Power cable |

|---|---|---|---|---|

| 0.4-0.6Mpa | Standard | – | AT3 | 5m |

| 0.4-0.6Mpa | Standard | – | AT3 | 5m |

| Filter cleaning function | Remote control feature |

Suitable for use in clean rooms *2

|

Dust collectionvolume capability

*3

|

Mass |

|---|---|---|---|---|

| Pulse type | OP | 20L | 125kg | |

| Pulse type | OP | 20L | 133kg |

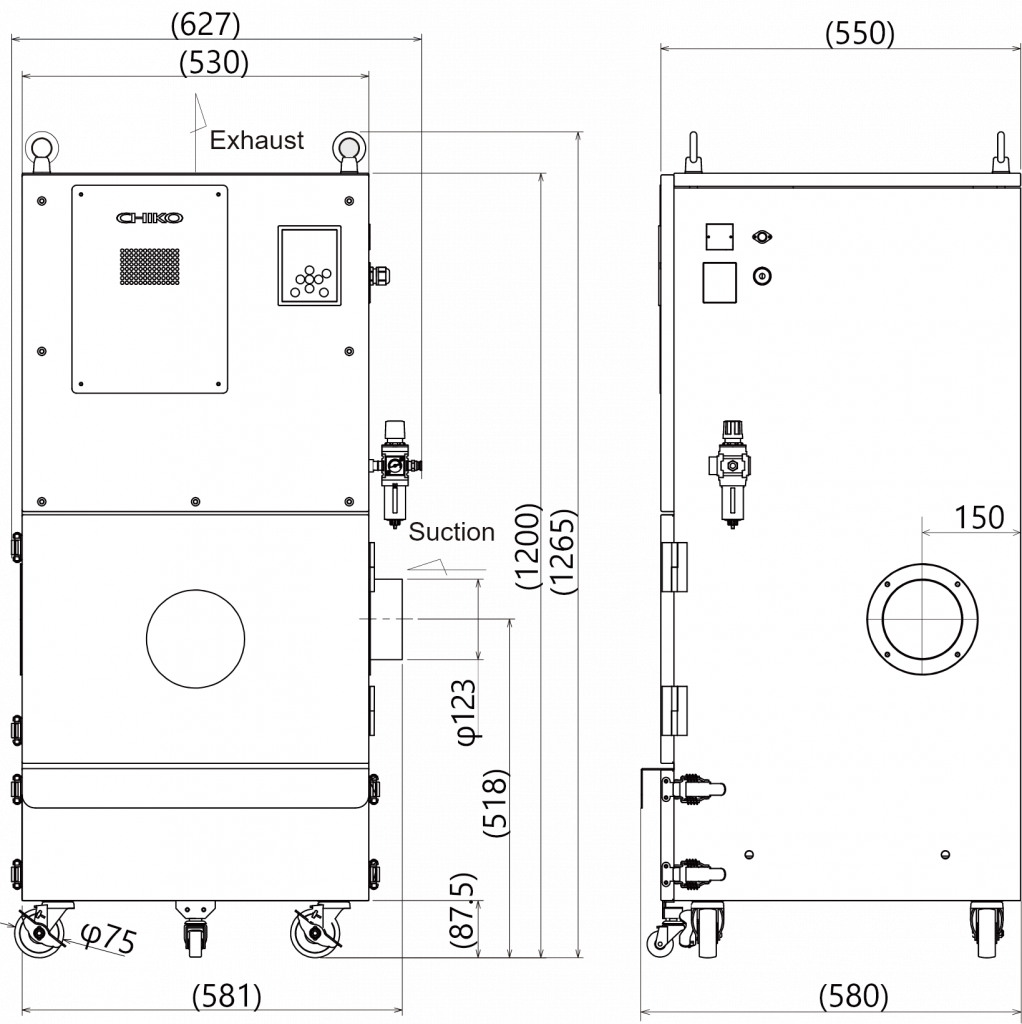

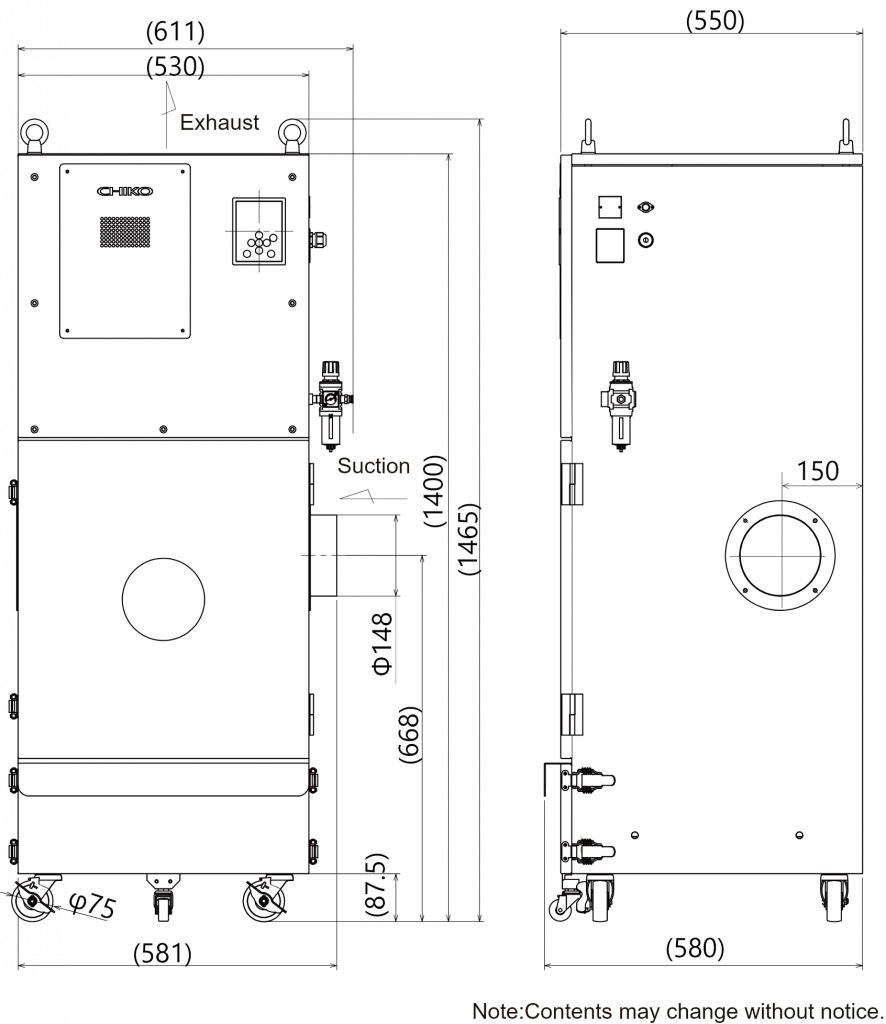

| Main body dimensions (D×W×H) |

|---|

| 580×581×1265mm |

| 580×581×1465mm |

CHIKO AIRTEC CO., LTD

2-27-24, Hakunoshima, Minoh,

Osaka 562-0012 Japan

E-mail:info@chiko-airtec.jp