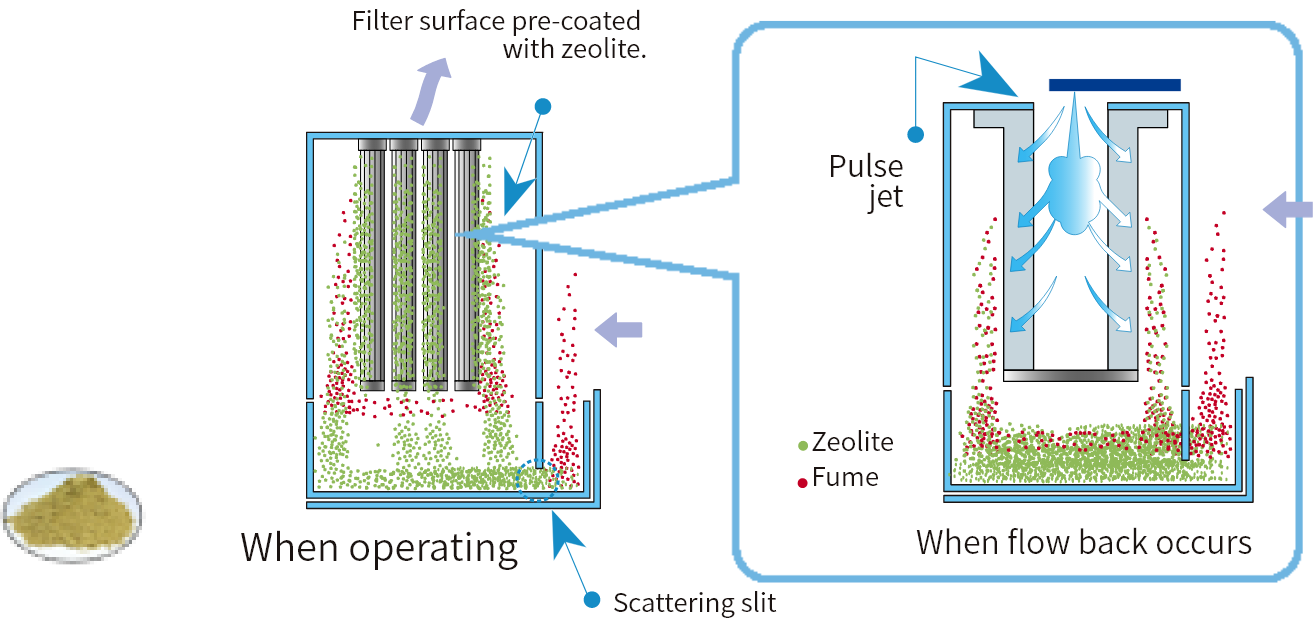

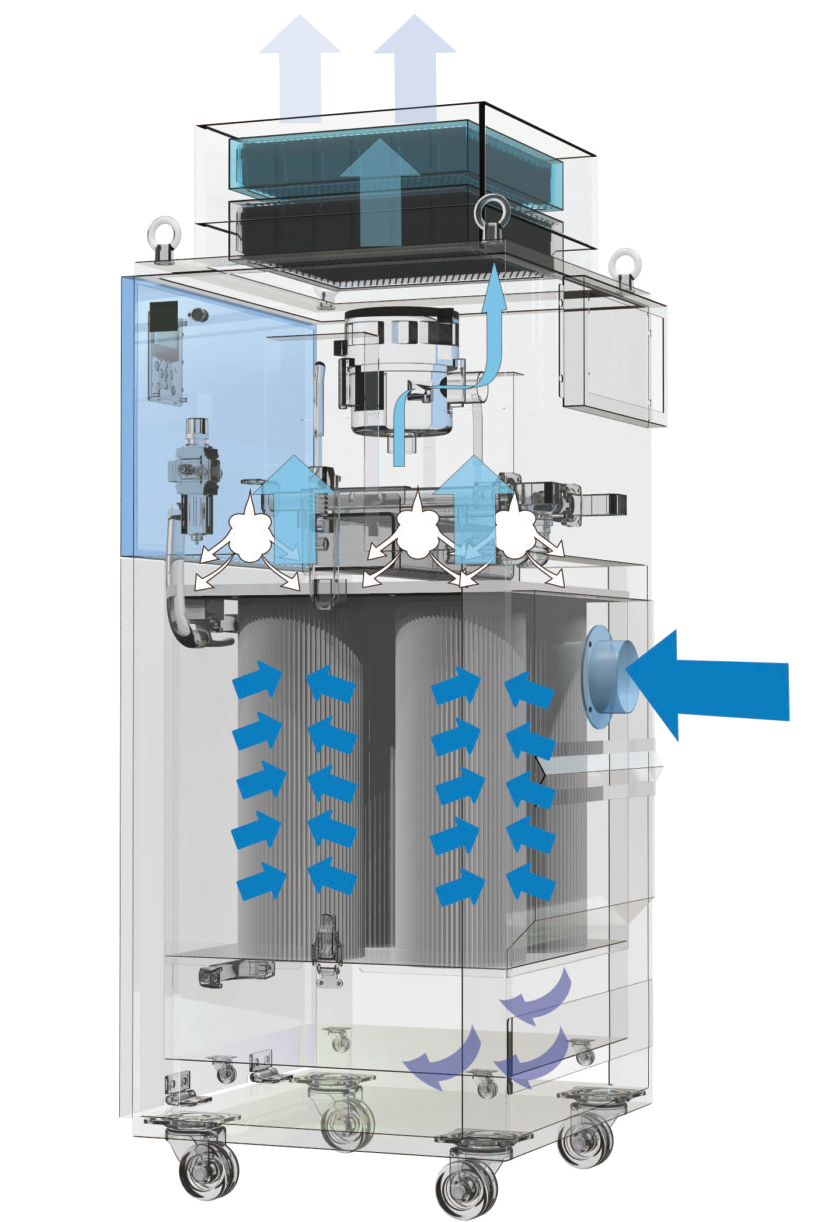

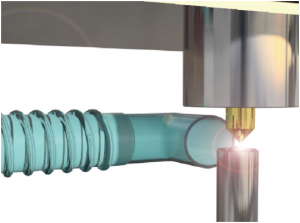

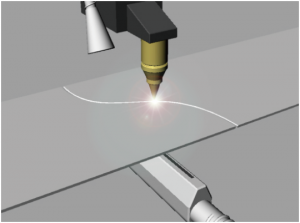

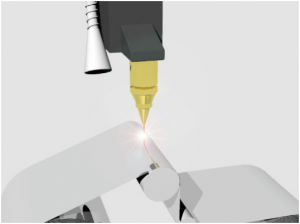

Dust collector with high static pressure and medium air volume for laser processing. Able to maintain a high suction power for a long time even under conditions where filter clogging is likely to occur, such as extraction of highly sticky fume generated by laser processing of collection of large volume of dust.

![]()

| Model | Primary filter | Secondary filter | Exhaust HEPA filter | Activated carbon |

|---|---|---|---|---|

| CHP-1600AT3 | CS-170-500-63P-R x 4 | CHF-3030-20 | HEP-4040-69 | ACC-4343-BOX |

| Motor cooling filter | Zeolite | |

|---|---|---|

| suction | exhaust | |

| PS/300N (90×150) | CHF-3517-30 | ZEO-5600(5.6kg) |

| Model | Output | Voltage | Frequency | Rated current |

|---|---|---|---|---|

| CHP-1600AT3 | 1200W | 200V (single phase) | 50/60Hz | 15.0A |

| Maximum air flow |

Maximum static pressure |

Noise level

*1

|

Suction port (hose) size |

Compressed air consumption volume |

|---|---|---|---|---|

| 7.0㎥/min | 9.5kPa | 60-68dB | φ100 | 27L/1 cycle |

| Compressed air pressure |

To be used with 200-240V |

CE compliant | Panel | Power cable |

|---|---|---|---|---|

| 0.4~0.5Mpa | Standard | – | AT3 | 3m |

| Filter cleaning function | Remote control feature | Suitable for use in clean rooms *2

|

Dust collection volume capability *3

|

Mass |

|---|---|---|---|---|

| Pulse type | Level 10000 | 18L | 160.0kg |

| Main body dimensions (D×W×H) |

|---|

| 680×620×1465mm |

CHIKO AIRTEC CO., LTD

2-27-24, Hakunoshima, Minoh,

Osaka 562-0012 Japan

E-mail:info@chiko-airtec.jp

CHIKO AIRTEC KOREA CO., LTD

#608 6F. 25-32, 116BUN-GIL, LS-RO, DONGAN-GU,

ANYANG-SI, GYEONGGI-DO SOUTH KOREA

E-mail: bh_lee@chiko-airtec.com